Column

Art of printing

If we define printing as the reproduction of many copies of a material using a pattern, then perhaps Gutenberg was not the father of printing. It is well known that wood block printing was already being done in 7th century China. In Europe, also wood blocks were used for printing patterns on cloth in the 14th century, and panel stamping was used for drawing patterns on leather using a metallic engraved plate. Again, stencils were used to color playing-cards. Gutenberg developed the letterpress printing technique using metal types made by combining these relief and intaglio techniques. His method is characterized by the following three aspects.

First his method uses arranged types to print ink onto paper, and many types must be prepared for each letter.

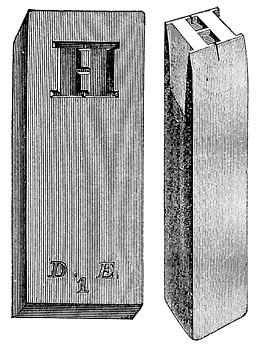

To make a type, first a punch, which is a key part of the process, is made cutting the letter into a hard metal such as steel. However, for parts that were difficult to cut out, such as independent holes, a counter punch corresponding to the hole was first made, which was then hit against the steel to make a hole.

When the punch was made, it was struck against a relatively soft copper plate to form a matrix. Then, two L-shaped blocks were placed on the matrix to make a casting mould, and an alloy of molten lead, tin and antimony or bismuth was cast into this mould, which was removed when the alloy had cooled down to produce the type. By repeating this process, a large number of identical types could be made for each letter. There must have been much trial and error before this method was established, including trying sand moulds, clay, plaster, and papier mâché as matrix materials. Some claim that certain kinds of types were actually made using these materials.

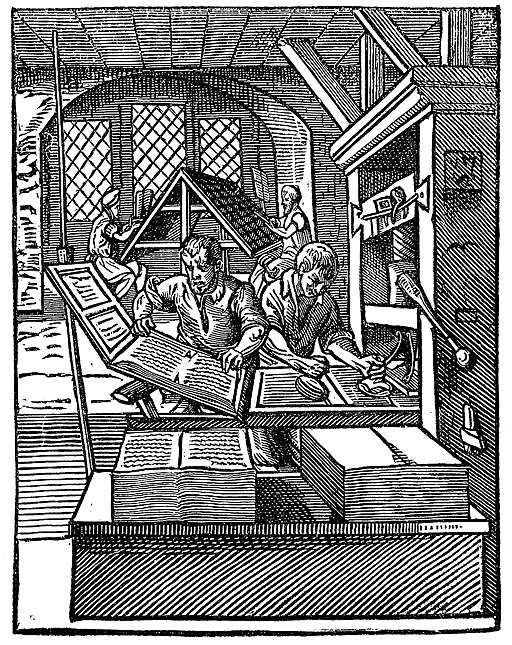

The finished types were kept in a case in the printing house, and a compositor arranged them to make a forme. In the process adopted in the 17th century, types were arranged in several lines within a frame called a "stick", and when the sticks for one page were prepared in this way, they were moved in a box called a "galley", and imposition (putting the pages in the correct order) followed. However, details of imposition in the era of incunabula are not known.

The second key element in the Gutenberg printing method is ink.

In the medieval period, scribes used black or brownish ink. Black ink was made by mixing charcoal or lamp black with gum arabic and glue. To obtain brownish ink, they crushed gallnuts into powder and dissolved it in water, then added ferrous sulfate (green vitriol) and gum arabic to the solution to induce a chemical reaction. To be suitable for printing, the ink has to adhere easily to the metal type and dry quickly. For this reason, linseed oil varnish was used as a solution imitating the oil paints used by painters. It has been found that Gutenberg used ink that contained lamp black and linseed oil, as well as walnut oil, turpentine oil, pine resin, cinnabar and other substances. The ink was produced by boiling down these materials, but its manufacturing method was kept secret by the printing house. It was not until the 17th century that the manufacturing method was revealed to the public. The pressmen first put the ink on an inkball made of sheep’s leather stuffed with cotton, hair, and other substances, and painted the forme with the ball.

The third key element is the press.

In order to transfer the ink from the typeface to paper, it was necessary to apply strong pressure. The model used was the wine press, a machine that generates strong pressure by applying the principle of the screw to squeeze grapes packed in a barrel. It is said that this machine had been invented by the 1st century B.C., and in the 15th century it was found in many wine producing regions. It is also said that machines that applied the same principle were used to press out water in the papermaking industry as well.

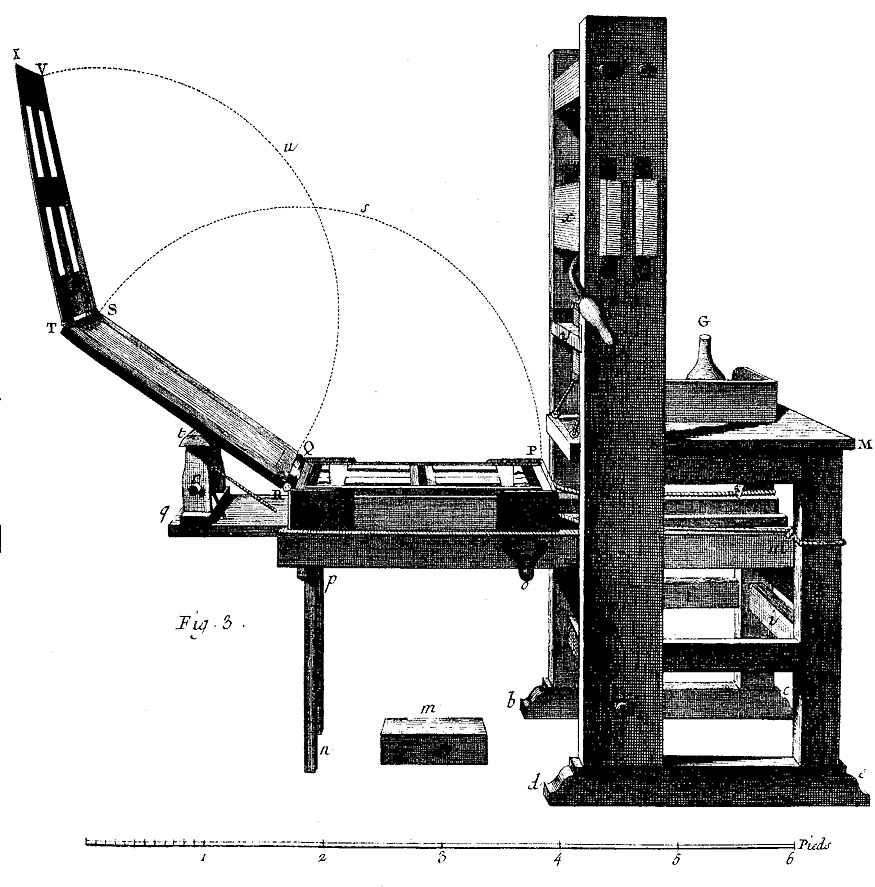

The first printing press built using this principle had a plate called a "platen" that pressed the paper hard against the forme. The platen had some upward and downward movement. Since it was necessary to apply ink to the forme every time one page was printed, the forme had to be moved to a point where more ink could be easily applied. For this purpose, the press was designed so that a thick plate called a "plank" with a pulley moved horizontally on the carriage. The plank was fitted with a wooden frame called a "coffin" and a press stone, and the forme was placed on the stone. The mechanism for the replacing paper used two wooden frames: one frame called a "tympan" fixed the paper; another frame called a "frisket" ensured that the ink was applied only where it was wanted on the page. Both frames were placed on the coffin overlapping each other. At the time of printing, the plank was moved to below the platen, with the two wooden frames overlapping. Since these wooden frames were joined with hinges and could be separated laterally, the paper was removed after pulling the coffin toward the operator.

The basic components of this printing press, which were called "feet," "cheeks," "heads," "caps," "winders," etc. were all made of wood. To power the press, the operator had to turn a bar by hand. Therefore, this machine is called the "common wooden hand press with screw". Various improvements were made to the printing press after Gutenberg’s invention, but the fundamental structure remained unchanged until the early 19th century. A printing press with an all-metal structure was devised by Earl Stanhope (1753-1816), a British statesman and scientist, and the steam-powered printing press was developed by Friedrich König (1774-1833), who also invented a printing press with a revolving cylinder (rotary press).